- 800.525.2690

- [email protected]

- Mon - Fri: 8:00 - 4:30

The Latest Industrial Hearing Conservation Trends

Explore the future of industrial hearing conservation with E.A.R., Inc. — leaders in custom-fit earplugs, fit-check verification, and smart hearing technology. From military to construction, industries are shifting from assumed to verified protection to improve safety, compliance, and worker health.

The Future of Industrial Hearing Conservation: Customization, Fit-Checking, and Smart Protection

In industrial environments where hazardous noise is part of the daily routine, hearing conservation programs have long focused on compliance — but the next frontier is individualization. With over 50 years in the hearing protection space, E.A.R., Inc. (www.earinc.com) has witnessed the transition from basic foam plugs to advanced custom-fit solutions and now to fit-check verification — the practice of ensuring that what’s worn actually works for the individual.

The Challenge: Assumed Protection vs. Verified Protection

Many industrial hearing protection programs rely on workers to self-insert disposable earplugs or wear earmuffs. But studies show that up to 60% of wearers achieve far less protection than the product rating suggests, often due to poor fit, improper insertion, or incompatibility with the worker’s anatomy or existing hearing condition.

This has led to the growing adoption of fit-checking protocols, which use objective, in-ear measurements to verify that a hearing protector is doing its job — on that specific worker, in that specific role.

Fit-Checking on the Rise: Military, Construction, and Beyond

Fit-checking has been widely adopted by the U.S. military, where the stakes are high and the need for both protection and communication is critical. In construction, where transient crews and dynamic noise levels make hearing conservation more complex, fit-checking is becoming a cornerstone of OSHA-compliant programs.

Looking ahead, it’s expected that fit verification will become standard across industrial accounts. This isn’t just about meeting regulations — it’s about protecting workers from permanent, preventable damage and reducing the costs of hearing-related claims, retraining, and workplace errors.

The Role of Custom-Fit Protection

Custom-fit earplugs and in-ear protectors offer consistent protection and improved comfort, especially in industries with long shifts or dirty, wet conditions where disposable foam plugs often fail. When paired with fit-checking, these solutions allow safety managers to document and verify attenuation levels, helping build robust, defensible hearing conservation programs.

These solutions are also ideal for workers with pre-existing hearing loss. Some models now incorporate amplification, directional microphones, and app-based tuning, providing both protection and performance in high-noise environments.

Technology Trends in Industrial Hearing Protection

Modern hearing protection is moving beyond passive barriers to dynamic systems that combine comfort, awareness, and adaptability. Key trends include:

- Custom-fit electronic earplugs — molded to the user for a perfect fit and consistent attenuation

- Bluetooth-enabled in-ear devices — allowing for streaming and communications integration

- Rechargeable hearing protectors — replacing disposable batteries for convenience and sustainability

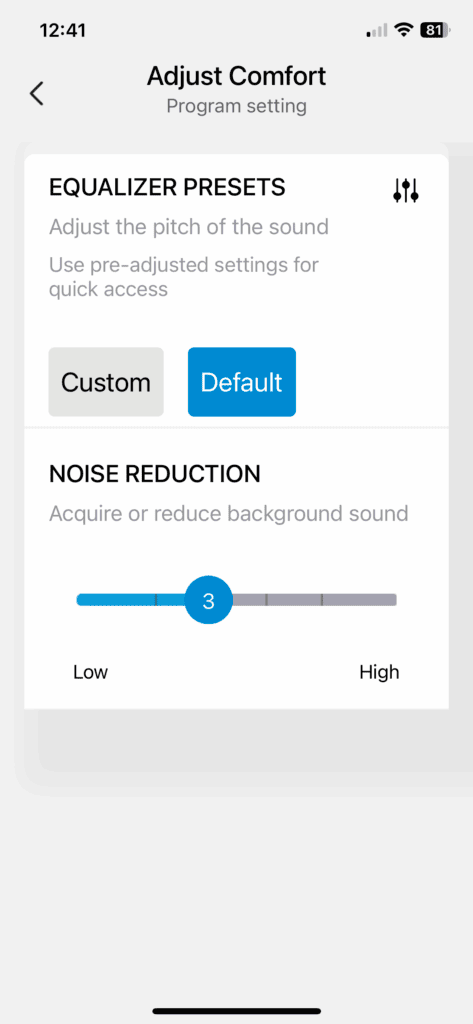

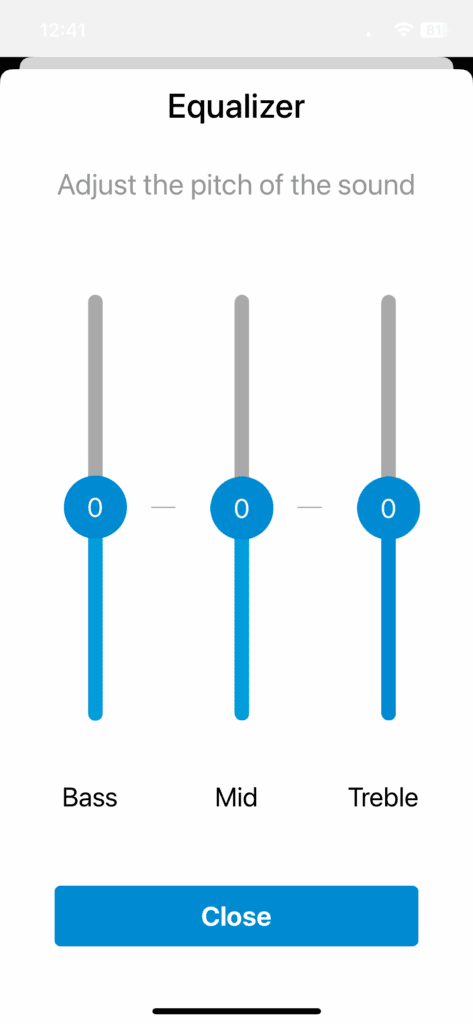

- Smart protection with programmable gain — adaptable to different job roles and hearing profiles

- Integration with fit-testing apps — enabling real-time feedback on insertion and effectiveness

- Hybrid devices — combining protection with environmental awareness, allowing wearers to hear critical warnings or team communication while staying protected

Smart Protection with Measurable Results

Advancements in electronic in-ear devices for industrial use allow for programmable filters, communication capabilities, and real-time noise monitoring. When combined with fit-testing systems (e.g., microphone-in-real-ear technology or field attenuation estimation systems), companies can now ensure:

- Each employee is wearing protection that verifies accurate fit.

- Attenuation meets the noise exposure levels of the specific job.

- Record keeping is traceable and defensible in audits or litigation

Closing Thoughts: Compliance Meets Care

Hearing conservation isn’t just a compliance checkbox — it’s a health and performance investment. Fit-checking, paired with custom-fit or smart hearing protection, ensures that every worker is covered, every day.

As military, construction, and manufacturing sectors adopt this standard, the rest of industry is expected to follow. For safety officers and program managers, the message is clear: The era of assumed protection is ending. The era of verified protection has arrived ins the U.S.A., Canada and many other parts of the world.

Related articles: