- 800.525.2690

- [email protected]

- Mon - Fri: 8:00 - 4:30

The Case for Hearing Protection Device Fit Checking

Authors: Robert M. Traynor, Ed.D., MBA, FNAP, Robert Traynor Audiology, LLC, Fort Collins, CO. Garry G. Gordon, M.S., CEO, EAR, Inc., Boulder, CO. Dennis Colucci, Au.D., Auditory Disorders and Balance Laboratory, Inc., Dana Point, CA. Article also published in Workplace Material Handling and Safety magazine.

INTRODUCTION

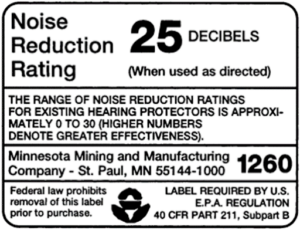

Since the 1970s, verification of the noise reduction (attenuation) provided by hearing protection devices (HPDs), using research level standards, resulted in the Noise Reduction Rating (NRR). This NRR designation is a laboratory-derived single-number designed to characterize a hearing protection device’s attenuation and as required by law is shown on the label of each HPD sold in the United States since 1979 (Figure 1). The result of this regulation was a rating that offers consumers a comparison method for HPDs as to the amount of noise reduction provided under laboratory conditions.

CONCERNS WITH THE NRR

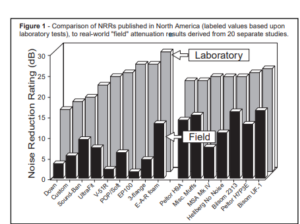

Franks (2024) describes the laboratory NRR assessment procedure as a Real-Ear Attenuation at Threshold (REAT). The REAT measure for NRR purposes is determined by measuring hearing thresholds of ten (10) normal-hearing members of a subject panel. The hearing thresholds for narrow bands of noise are measured in Sound Pressure Level (SPL) in a highly specified acoustic environment. Each subject is evaluated twice, first ears open and, secondly, ears occluded with the HPD in place. Rather than allowing the subject to insert or remove the HPD, the experimenter best fits the hearing protection device to the ear of each test subject for each occluded test. Each subject repeats the paired open/occluded assessment three (3) times. The calculated single number NRR is the averaged REAT difference in SPL between threshold assessments with the ears occluded and the ears open. Thus, theoretically, the higher the NRR, the greater the noise reduction. While this deduction was the point of the NRR in 1979, there has been substantial study of the reliability of the NRR measurement. However, it is well known across the world that the NRR may overestimate the attenuation offered by HPDs by at least 50% for several reasons, such as poor fit due to ear architecture, improper insertion, or the lack of comfort. Thus, the values measured were not in agreement with their published ratings. As early as 1996, Berger and colleagues found substantial differences between the data obtained in the laboratory and those found in the field (Figure 2).

As a result, employees with significant threshold shifts were identified through audiometric evaluations and advised and provided other options, such as custom HPD’s and procedures to minimize the risk of further hearing loss. Employers want to protect employees but also reduce their workmen’s compensation exposure. This fit and individual issue has been noted by all hearing conservation organizations, such as OSHA, NIOSH, and others.

Gauger & Berger (2004) state that although the laboratory data were representative of the group average for subjects using the device, individual variability is large enough that attempts at predicting a person’s performance from group data can easily err by 20 dB. Murphy & Franks (1998) summarized the studies of the reliability and relevance of NRR as having a lack of relevance to the real world. Even professional engineers familiar with the NRR and its concerns state that the NRR is seldom achieved in the real world (Behar, 2019).

While there are some technical concerns with the NRR and its use within hearing conservation, another realistic concern is the lack of general consumer understanding of how to use the measurement when purchasing HPDs. Consumers assume that when presented with a level of noise exposure at 100 dB, wearing hearing protection devices with an NRR of 33dB would reduce their noise exposure to a safe level of 67 dB (100 dB – 33 dB =67 dB). However, the general public does not understand the adjustments made to methods of noise measurement. Due to the methods used to measure noise, there is a calculation on the NRR that must be conducted to arrive at the actual amount of protection. The formula described by Berger (2000) is referred to as the “devalue” of the NRR determines the actual amount of noise reduction created by a specific HPD with an NRR rating. For example, for a HPD with a 33 dB noise reduction rating (NRR), subtract 7 dB from the rating, and then divide by two to arrive at an estimation of the actual noise reduction to the ear. Given the previous example, the actual noise reduction equation would be (33-7)/2 =13. This means if the subject was exposed to 100 dB using hearing protection rated NRR 33 dB, the actual reduction of the noise would be estimated to be 87 dB, which is above the OSHA Permissible Exposure Level (PEL). When fit checking is not conducted, this is the method of predicting the effectiveness of NRR plugs and muffs.

FIT CHECKING OF HEARING PROTECTION DEVICES

Fit-test technology has been available for over 40 years to assess and reduce the personal variables referred to in the NRR ratings, although individual use still remains an important factor for hearing conservation professionals.

Traditional Methods of Fit Checking

Madison & Schultz (2020) present the traditional methods of fit checking to ensure that attenuation is provided by HPDs:

- Visual Check. Visual observation of complete insertion of the HPD into the ear canal with resistance when it is tugged or pulled.

- Acoustic Check. When earplugs are correctly inserted, the user holds cupped hands over their ears while listening to a noise source. If there is no subjective difference in the intensity of a noise source when cupped hands are placed over the ears, and without, the earplugs are properly inserted and provide attenuation.

These methods are routinely incorporated in hearing conservation programs by trained technicians to ensure that the company’s chosen hearing protection devices provide attenuation. The assumption is that an employee using an HPD with an appropriate devalued NRR for company conditions with proper insertion, with attenuation will protect the user from hazardous noise exposure. In today’s hearing conservation programs, hearing conservation technicians are trained to instruct workers to verify their individual HPD attenuation using visual and acoustic methods. For OSHA compliance, however, the specific amount of individual noise reduction afforded by the HPD, or the acquisition of a Personal Attenuation Rating is not required.

Personal Attenuation Rating

Although theory would suggest that these cursory methods of fit checking provide the devalued NRR attenuation of the hazardous noise, they do not provide specific attenuation data relative to a particular individual with a specific HPD in place. Although there may be attenuation, typical visual and acoustic checks offer no indication of individual differences in actual noise reduction using a particular earplug. The problems with HPD attenuation effectiveness, as measured by the NRR (even devalued), are summarized by Voix et al (2022):

The devil is in the details: how to train and motivate employees to fit their hearing protection devices (HPDs) correctly and consistently, how to assign HPDs proportionately to noise exposures, and how to accommodate personal preferences and anatomical variations.

An individual, frequency specific, attenuation measurement is called the Personal Attenuation Rating (PAR). Berger (2010) describes PAR as:

A “personal attenuation rating” for a given hearing protector can be used to estimate the noise attenuation achieved by the individual for whom it has been measured. It can be directly subtracted from an A-weighted sound pressure level (dBA value) to predict that person’s protected noise level or exposure.

There are two general methods to obtain a PAR: the REAT Method and the Field Microphone in Real Ear (F-MIRE) technique, which uses modified probe microphone equipment used in hearing aid fitting since the 1980s.

Real Ear Attenuation at Threshold (REAT)

Many of the newer audiometric assessment systems for hearing conservation programs have a fit check system incorporated within their equipment. Products such as the Benson, Fit Check Solo, and WAHTS, (Figure 3),

are examples of systems that incorporate a REAT system for the actual measurement of a PAR.

The employee is assessed with and without HPD occlusion, and the software calculates the real ear attenuation at threshold, providing the amount of actual noise reduction by the HPD. This PAR value can be used to document the projected noise exposure of a worker to increase hearing safety in the workplace.

Field Microphone in Real Ear (F-MIRE)

As the use of probe microphone systems gained steam within the verification of hearing instrument fittings, early researchers considered the possibility of measuring the attenuation of hearing protection devices (Traynor et al., 1989). For those concerned about improving the selection and use of hearing protectors, the new science of probe microphone verification offered a reliable, objective method of measuring the attenuation of HPDs in an individual’s ear.

The current F-MIRE method (Berger, 2007) uses a small microphone with two elements, one of which is placed inside the ear canal and the other outside. The data, calculated from the difference measured by the two microphones, determines an individual’s Personal Attenuation Rating (PAR) for a particular HPD against a test noise . Thus, these data can directly determine if a particular HPD provides adequate attenuation for a specific hazardous noise environment across frequencies. Test results are reported as PAR, and similar to devalued NRR scores or the REAT technique, the higher the F-MIRE PAR value, the greater the noise reduction capabilities of the HPD when fitted properly.

For F-MIRE and the REAT techniques, however, the value is a real, on-site score for the individual employee, not a score achieved in a laboratory, so there is no devaluation necessary. Even with this exceptional technology, the long-term results still depend on the user of the HPDs. Murphy et al (2011) felt that an additional benefit of either the REAT or the F-MIRE techniques is the opportunity for the technicians, to teach and train every employee on proper earplug insertion and use while reinforcing the need for continuous protection at work and off the job. Morata et al. (2024) indicate that the published research regarding the efficacy of hearing protection device fit-testing systems and associated training in reducing workers’ noise exposure has increased the use of these procedures.

Currently, the REAT or the F-MIRE hearing protection device fit check procedures are only a mandatory hearing conservation requirement for programs within the Department of Defense (DOD, 2023). According to Hayes (2023), OSHA Letters of Interpretation regarding the fit checking of hearing protection devices have been recognized as a best practice by OSHA since 2008 but are not yet mandatory. While the PAR measurement is required by the US military and considered best practice by OSHA, other countries, such as Europe and Canada, have adopted it as a required component of their industrial hearing conservation programs.

Several companies have opted to conduct fit checks only with new hires and those who may have demonstrated a threshold shift. While this may be due to time and funding constraints, offering this procedure to all employees enrolled in the hearing conservation program benefits the company and the employee alike.

- Knowing the actual PAR value conducted by either technique will verify the performance of a specific HPD at the time of fitting. These procedures document the company’s efforts toward the requirement to provide adequate hearing protection for workers in hazardous noise environments.

- REAT or F-MIRE assessment can be part of routine audiometric exams provided by trained technicians and only adds about 10 minutes to the procedure. To demonstrate the company’s commitment , these procedures need to be documented in the hearing conservation program’s records for each worker.

- For the employer. They are using a procedure that is considered best practice by OSHA as it assesses the suitability of the earplugs provided by comparing the actual attenuation achieved with attenuation expected from the NRR label. It also fulfils regulatory requirements for training with documented results. Moreover, they are protecting their workers against permanent hearing loss and possibly fewer compensation claims.

- For employees. Fit testing demonstrates the importance of hearing protection in the workplace and helps employees select and compare protectors to find the best choice for their ears and specific noise environments. The procedure documents that as long as they use their HPDs correctly, they will be protected from permanent occupational hearing impairment. The result is improved employee confidence in and compliance with the company’s hearing conservation program.

Does Fit-Checking Reduce Workmen’s Compensation Claims?

Fit checking for hearing protection devices can be an invaluable tool in reducing compensation claims for noise-induced hearing loss in the workplace. If there are problems that come up within your program, hearing conservation program managers should contact a forensic audiologist to assist with any possible legal cases.

Fit check records can provide documented evidence that the employer used scientifically proven methods to select appropriate hearing protection devices for specific workers and trained them in their proper use. This level of powerful documentation has been unavailable to hearing conservation programs in the past. While the equipment and extra assessment of workers may add to the expense of the program, fit checking of HPDs could save much more than the program’s cost in unnecessary legal compensation cases.

References:

Berger, E., Franks, J., & Lindgren, F. (1996). “International Review of Field Studies of HPD Atten.,” In Scientific Basis of NIHL, eds. Axlesson, et al., Thieme Med. Pub., New York, NY. 361-377.

Berger, E. (2000). The Naked Truth About NRRs. EARlog, Aaero, Laboratory 7911 Zionsville Road, Indianapolis, IN.

Berger, E. (2007). Introducing F-MIRE Testing: Background and Concepts. Hearing Review, Vol 14(30). Retrieved September 25, 2024 from

https://hearingreview.com/hearing-products/accessories/components/introducing-f-mire-testing-background-and-concepts#comments

Berger, E. (2010). What is a personal attenuation rating (PAR). E-A-R 07-21/HP. 3M Occupational Health & Environmental Safety Division, E•A•RCAL, Laboratory 7911 Zionsville Road, Indianapolis, IN.

Behar, A. (2019). The NRR: The Good, The Bad, and The Ugly. Canadian Audiologist, Vol 6(3),

DOD (2023). Hearing Conservation Program. DOD Instruction Chage 1., 2023. Office of the Under Secretary of Defense for Personnel and Readiness, Department of Defense, November 2023.

Franks, J. (2024). The Quantification and Reporting of Hearing Protection Attenuation. Canadian Audiology, Vol. 11(5).

Gauger, D. & Berger, E. (2004). A New Hearing Protector Rating: The Noise Reduction Statistic for Use with a Weighting (NRSₐ), US Environmental Protection Agency.

Hayes, M. (2023). Hearing Protection Device (HPD) Fit Testing. MidAtlantic Regional Conference in Occupational and Environmental Medicine, Johns Hopkins Center for Occupational Safety and Health, Baltimore, MD.

Schultz, T., & Madison, T. (2020). Hearing Protection Devices, In Hearing Conservation Manual, 5th Edition, Eds, Hutchinson, T., & Schultz, T. Council for Accreditation in Occupational Hearing Conservation.

Michael, P., Kerlin, R., Bienvenue, G., Prout, J., & Shampan, J. (1976). Real Ear Field Method for the Measurement of Noise Attenuation of Insert-type Hearing Protectors, National Institute for Occupational Safety and Health, US Department of HEW, Cincinnati, OH.

Morata, T., Gong, W., Brogan, A. (2024). Enhancing Workplace Safety: A Systematic Review of Hearing Protection Fit-Testing Systems and Training, NIOSH Neuroscience Blog, Center for Disease Control, Atlanta, GA

https://blogs.cdc.gov/niosh-science-blog/2024/07/30/hearing-protection-fit-testing/

Murphy, W., Stevenson, M., Byrn, D., Witt, B., Duran, J. (2011). Effects of training on hearing protector attenuation. Noise and Health, Vol 13(51), pp. 132-141.

Traynor, RM., Ackley, RS., and Wierzbowski, LR. (1989). Probe tube microphone measurement of hearing protection devices, Hearing Instruments, 40(2)

Voix, J., Smith P., & Berger, E. (2022). Chapter 12: Field Fit-Testing and Attenuation-Estimation procedures. In The Noise Manual, 6th Edition, (Meinke, D., Berger, E., Neitzel, R., Driscoll, D., & Bright, K., Eds.) American Hygiene Association, Falls Church, VA.

About the Authors

Robert M. Traynor, Ed.D., MBA, FNAP, Robert Traynor Audiology, LLC, Fort Collins, CO.

Garry G. Gordon, M.S., CEO, EAR, Inc., Boulder, CO.

Dennis Colucci, Au.D., Auditory Disorders and Balance Laboratory, Inc., Dana Point, CA